Andrew Huang's Blog

October 30, 2025

Name that Ware, October 2025

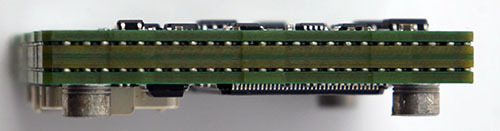

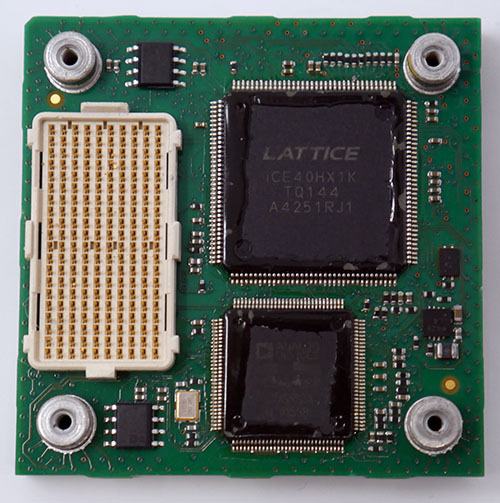

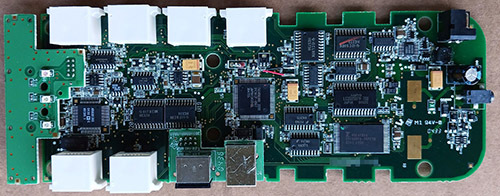

The Ware for October 2025 is shown below.

Thanks to Juan C. for contributing this curious ware!

I really can’t get enough of how the whole device is integrated with a multi-layer stacked PCB. I imagine that inside the middle of the stack there could be some interesting circuitry going on, too.

I redacted one part number to try and make things a smidge more challenging; at least, an LLM wasn’t able to outright guess the ware when that part number was omitted (but of course, the spirit of the game is to sharpen the wetware sitting on your shoulders by trying to reasoning about the function of the ware, with the aid of reference searches to find datasheets, learn theory, etc).

Winner, Name that Ware September 2025

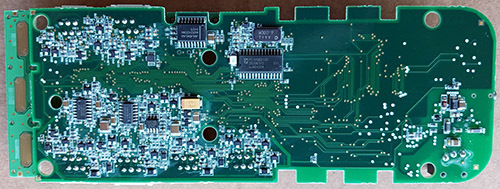

The Ware from September 2025 is a Hotronic AF 75 time base corrector. Really great comment thread, it was fun to read the sleuthing work and thought process behind the guesses. And yah, those SRAM chips make me nostalgic – I remember how expensive those were! Back when 32kiB cost real money.

A couple folks had guessed a time base corrector out of several possibilities, but I like how Guy Dunphy backed his guess up with an explanation of how it works. So, I’ll give Guy the prize this month. Congrats, drop me an email to collect your prize!

September 30, 2025

Name that Ware September 2025

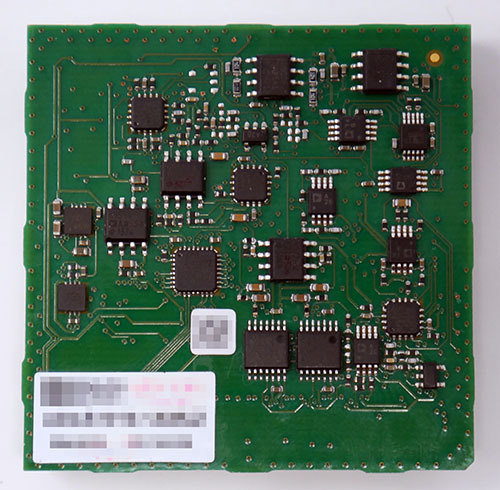

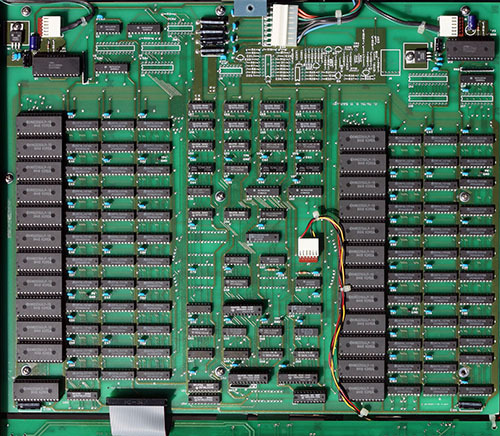

The Ware for September 2025 is shown below.

Thanks to Michael Dwyer for submitting this ware! I originally contemplated only showing the digital board to make the ware more challenging, but the analog part is so chaotically gorgeous I had to share it out of the aesthetic appreciation.

Despite the size and complexity of the system, there is no CPU. There was a day and age where it was fairly common to design systems without one. In many cases, a ROM-based FSM was more economical, offering better performance and consistent timing. This gave them an edge over MCUs when the flexibility afforded by a programmable instruction set was offset by higher component costs and the difficulty of working with variable-length, multi-cycle instruction execution timings.

Winner, Name that Ware August 2025

The Ware for August 2025 is the Superboard II from an Ohio Scientific Challenger 1P. Congrats to Tibor Bartos for naming it. Email me for your prize!

September 13, 2025

Use the Force (Feedback) to Solder Small Things

Here’s a quick tip for people learning how to solder small components: don’t rely on your eyes. Instead, solder by touch: use the force-feedback available through your fingertips. Human fingers can reliably detect bumps on the order of microns in size – much finer than the resolution of sight, even with the assistance of a decent microscope.

I use my eyes to get the components “about there”, and then switch to using fingertips for feedback. Really focusing in and just relying on vision for alignment tends to increase hand-shake. At least for me, the neurological delay on the loop from eye-to-motor control is longer (and more noisy) than the loop on tactile-to-motor control. So, I keep my eyes open, but allow them to wander slightly so I’m able to pay more attention to what I’m feeling with my fingers.

Try this out: drag a soldering iron tip across PCB traces or soldermask while averting your eyes (closing your eyes entirely might be too disorienting without a bit of practice). As you drag across the traces, you’ll notice a “bump” every time you encounter one. Do the same for pins on tiny components. Practice with a cold tip to get a feel for things, then add heat; pay attention to how the textures change with temperature. Eventually, you’ll be able to tell when the tip of the iron has met its mark by how it feels. Sometimes you can tell you’ve made a good solder joint just by how the metal feels as it melts; you can also tell when your tip hits a pin connected to a copper plane because the solder on the tip will freeze briefly on contact with the cold copper.

Likewise, the reason I use fine-tipped titanium tweezers isn’t because it’s better for gripping components – it’s because the stiffness of the titanium gives intimate feedback about the texture of the PCB & components. It’s also the same reasoning I use bare surgical scalpels to cut traces; if you mount the blade in a handle, you lose tactile feedback on what the blade is doing.

The other pointer I have is that efficient soldering happens not at the geometric tip of the iron, but rather at the spot where the solder is liquid on the tip (and if you don’t have shiny, liquid solder on your tip, clean the tip and put a small dot there). I’ve observed a tendency for beginners to use soldering irons like ball point pens, but in reality the surface tension of solder always pulls the liquid away from the point of the tip. If your components and pads are oxide-free (e.g. through the use of flux), the “right” amount of solder from a much larger liquid solder reservoir will disperse onto the solder joint through the laws of physics (via surface tension), assuming that your board was made using a modern solder mask formulation that naturally repels liquid solder.

Above, foreground: knife-edge soldering tip, with a dot of liquid solder near the point; background shows bare surgical scalpels and titanium tweezers.

This is one of many reasons why I prefer to use the “knife edge” soldering tip versus conical tips; the knife-edge’s versatile shape has a natural landing spot for liquid solder adjacent to a thin linear edge, backed by ample heat capacity. The effective geometry of the soldering point can be varied by adjusting the angle of attack relative to the work piece: the very end of a knife-edge is effectively a conical tip, while the blade is effective at delivering lots of heat and solder. It is often the tip of choice at many factories that I’ve toured. In the hands of an experienced operator, one can balance throughput and precision without changing tips, and it’s good for everything from through hole to fine-pitch TQFP, while also being effective at desoldering a range of small components.

August 17, 2025

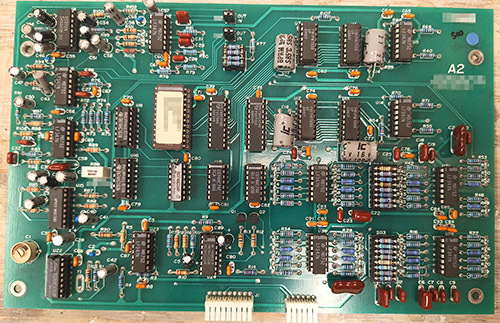

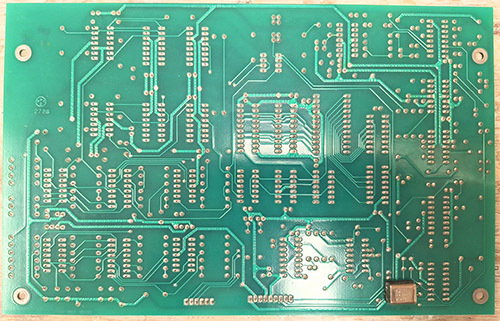

Name that Ware, August 2025

The Ware for August 2025 is shown below.

Thanks to Curtis Galloway for contributing this bit of nostalgia! This board has the look of one that was laid out by hand using masking tape or rubylith – back in the day before computers became affordable and powerful enough to regularly use them for making new computers. It also looks hand-soldered, instead of wave-soldered. I only ever designed a couple of boards using tape, but even today I’m still hand-soldering boards – BGAs, 0201’s and all. I do a lot less of it than I used to, but you still gotta fix bugs and hack things the old fashioned way.

Winner, Name that Ware July 2025

The Ware for July 2025 is a Vernier Lab Pro. While researching the ware with FETguy, we noticed that the OEM for the product is probably Inventec, which also made a line of products for TI calculators at the time. That particular OEM design team applied its design language in several products. I’ll give the prize to Jin who got the exact make and model of the board. Congrats, email me for your prize!

July 29, 2025

Name that Ware, July 2025

The Ware for July 2025 is shown below:

Thanks to FETguy and Renew Computers in San Rafael, California for contributing this ware!

Winner, Name that Ware June 2025

The Ware for June 2025 is a Gentner EFT-900A frequency shifter for radio audio applications. According to Chris Combs, “it lets two parties send and receive ‘full-range audio’, whatever that means, compressed and then decompressed via the usual 300-3500hz phone line”. Even though Per named the ware first, I will give the prize to Kienan because the response addresses the theory of operation of the ware – shifting the audio up/down by 250Hz so that low-end audio isn’t lost on analog telephone lines. I found that bit very insightful, and now I don’t look at the ware the same way as I did before. Congrats, email me for your prize!

Also, this has never happened before, but the designer of the ware (Bill Gillman) made a cameo in the comment sections. I really enjoyed looking at the board, so as a token of thanks for designing such a nice ware, email me and I’ll also give you a prize.

June 30, 2025

Name that Ware, June 2025

The ware for June 2025 is shown below.

A big thanks to Chris Combs for this handsome contribution! Despite being 80’s vintage, the board is in mint condition.

Andrew Huang's Blog

- Andrew Huang's profile

- 32 followers