Aaron U. Bolin's Blog

April 25, 2019

Process Simulation - Before and After

Here’s a somewhat unique solution to the Lean Six Sigma Green Belt Statapult Simulation.

This team removed four positions (customer liaison, process observer, sorter, and time observer), eliminated unnecessary paperwork, automated the ball return, standardized the ping pong ball, and stabilized the catapult.

While not a world-record setting performance, they get bonus points for labor efficiency.

November 19, 2018

From Activity to Effectiveness: Unifying Efforts with a Common Vision and Roadmap

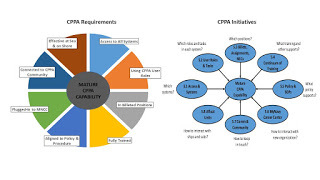

In 2012, the Navy reorganized the administration of pay and personnel under a consolidated organizational hierarchy. Part of the reason for the reorganization was to improve the capabilities and standardization of the Command Pay and Personnel Administrators (CPPA).

Work began immediately on improving systems for CPPAs, improving training for CPPAs, improving policy for CPPAs, etc. The work was somewhat unbalanced though, because some streams of the development could proceed much more rapidly than others. In fact, the difficulty surrounding lack of synchronization among the development streams created significant friction on more than one occasion.

Because the pace of improvements accelerated in 2017-2018 to coincide with other developments around the domain, these lack of synchronization difficulties became unbearable.

Through a series of weekly meetings with a cross-section of stakeholders, we carefully documented requirements for a mature CPPA capability and then mapped these requirements to existing and future initiatives (see figures above).

Although documenting and synchronizing requirements and initiatives is not an original idea, the benefits were immediate and unmistakable. Many of the existing synchronization issues vanished through simple conversation among the stakeholders, and development for slow-moving streams accelerated by giving them higher priority in the development stack. More importantly, we began to see small but measurable improvements in CPPA performance that could be tied directly to the now unified vision and roadmap. Simply having a planned roadmap made the trip run more smoothly.

November 6, 2018

AISES and SWE 2018

I continued to support the Navy’s recruiting mission in 2018 by attending the American Indian Science and Engineering Society conference and the Society of Women Engineers conference. At the conferences, we provided instruction in lean six sigma fundamentals as a way to support the conference communities and to acquaint participants with Navy career opportunities. We also participated in the career fair to have a better opportunity to share details with individuals interested in Navy career paths.

March 30, 2018

Lean Six Sigma Milestone: 1,000 Students

A total of 82 students packed a room designed for 50; somewhere in the room is my 1,000th student!

The good news is that the demand for Lean Six Sigma content remains strong; young professionals clearly see the link between process improvement skills and career advancement.

If there is bad news, then it lies in the Navy's drifting away from the tools and techniques of Lean Six Sigma toward other process improvement systems.

This may in fact be the end of a chapter --- we are now looking ahead to DESIGN THINKING as a way to improve Navy processes.

DESIGN THINKING captures the basic essence of Lean Six Sigma, but it focuses more deliberately on design from an end-user's perspective.

Okay, so now it is time to find my first DESIGN THINKING student!

December 19, 2017

Everyone Likes to Win!

The command emphasis on lean six sigma has shifted and now focuses on a simplified approach that centers around Lean Kata.

I've also switched roles which means I do a lot less training nowadays. I'm not sure if I'll ever get a chance to reach the 1,000 lean six sigma student milestone.

However, one thing has been constant. Regardless of the composition of the students, regardless of the simulation used, and regardless of the setting --- everyone like to win.

Something about a team-based problem solving simulation is very intrisinically motivating, especially when coupled with competition.

If I could bottle this level of motivation and bring it back to the job site, process improvement would explode.

The winning crew from the most recent course is pictured here. Although they didn't break any world records, they did a nice job of eliminating waste, reducing variation, and managing bottlenecks.

Congrats to the Ballers for a job well done.

October 19, 2017

Packing the Room at Society of Asian Scientists and Engineers National Conference

The attendees were very engaged throughout the workshop and left with a fundamental understanding of lean, six sigma, and theory of constraints.

Note to the fire marshal: we stayed within the 159-person room capacity limit.

September 26, 2017

Just Hanging Out with an Astronaut

August 29, 2017

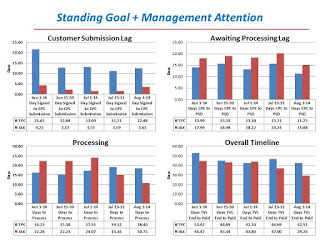

Hawthrone Effect, Theory of Constraints, and Travel Claim Processing

For decades, the standing goal for travel claim processing has been 30 days from the end of travel (TVL End) to paid. Conventional wisdom viewed the standing goal as somewhat unrealistic though, because a portion of the timeline is dependent on the customer's timeliness. Wisdom says that if the customer submission lag is very long, then the travel claim processor cannot meet the 30-day goal.

In mid-July, a large backlog of claims at JAX caught the attention of upper management. The backlog was not unusual, but management interest in the backlog was something new. Upper management began to pay a lot of attention to the JAX travel claim processing operation and communicated this interest with frequent inquiries.

Without any additional resources, the JAX team shifted into high gear and wiped out most of the backlog by the end of the month. TPC is a second processing location and is included in the charts as a point of reference. The charts show that JAX had done a good job of training its customer base to submit claims promptly, but they were squandering this advantage by keeping a large backlog awaiting processing and by processing at a slow rate. Once these two issues were corrected, JAX broke with conventional wisdom and met the standing goal.

May 15, 2017

American Indian Science and Engineering Society Leadership Summit 2017

At the AISES Leadership Summit, I had the opportunity to deliver a white belt workshop while in uniform. It was a great way for me to support the active duty recruiting mission as a reservist.

Students and professionals from all over the country converged in Chandler, Az to celebrate the contributions of Native Americans in science and engineering. We trained a small group in the principles of Lean Six Sigma in preparation for the larger national convention later this year.

February 7, 2017

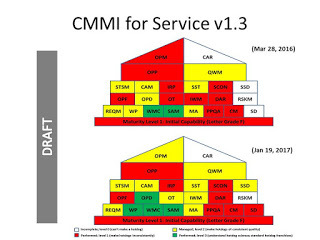

Capability Maturity Model: Reassessment

We also discovered that understanding the CMMI model is a lot easier if you can anchor the conversations in a concrete analogy. We chose hotdogs. As we went through each of our focus questions, we compared our operations against a hotdog stand. So, for Requirements Management (REQM), we asked, "if we were a hotdog business, what level would our requirements management process fit?" At level 0, we are not currently making hotdogs (i.e., not doing Requirements Management). At level 1, we can make hotdogs but we do so inconsistently (i.e., we do Requirements Management sometimes but not others). Each area has several focus questions that are very specific.

Another really useful part of this exercise was the impact it had on our strategy moving forward. The CMMI informal assessment made us realize that we were focusing on things in the wrong order. The visual analogy of a pyramid structure helped us realize that we needed to focus more of our efforts on completing the base of the pyramid, things like consistent Service Delivery (SD), before trying to develop a comprehensive Risk Management (RSKM) plan that was higher up.

In January of 2017, we repeated the process. Although we made some progress, we still got an 'F' as a final grade. There are 1,000 reasons why we didn't make more progress, but the reassessment results are actually a good news story. Our more focused efforts strengthened our foundation, and the momentum generated by that focus will be exponential. I expect us to have moved into the 'D' range by summer's end and into the 'C' range within a year. At that time, we may start looking at a formal independent assessment --- one that is a little more objective.

Tons of maturity model information is available at SEI (http://www.sei.cmu.edu/).