Rahul Guhathakurta's Blog

September 4, 2018

Cognitive Automation — Going beyond Rule-based RPA

By Rahul Guhathakurta

In recent times, organizations across the world from various industry sectors are pushing themselves to become "Digitally Native" by adopting "Digital Transformation" as a foundational pillar for the future — starting with Robotic Process Automation (RPA). And, the primary objectives for the most of them are to achieve speed, accuracy, and reduction in headcounts. The convergence of RPA, artificial intelligence (AI), machine learning (ML), natural language processing (NLP), and cognitive platforms is potentially so disruptive that Klaus Schwab, founder of the World Economic Forum, calls it the "Fourth Industrial Revolution."

At the same time, there is a good share of apocalyptic warnings from various quarters that the advancement of automation (cognitive form) in the workplace will create a "dystopian society". To nullify such warnings, Karen Lachtanski aptly wrote, -"If an argument is to be made against digital transformation, it is that the divide between high-level skills and low-level skills will become wider, with little or no middle ground." In short, she clearly states that there is no time to dwell on it. What going to set the future workforce apart is what we as a part of that workforce are willing to do about it i.e, learn and evolve (or simply perish).

Flowchart Attribute: Sample Automation Architecture for Banking Solution/Financial Services Source: Virtusa

What is Robotic Process Automation (RPA)?

RPA is a basically a software tool that can automate routine tasks/sub-tasks in structured mannered by eliminating human activities such as "copying and pasting data between multiple applications" so that functional/cross-functional teams can focus on more value-adding activities.

In December 2017 survey by Deloitte , "53% of the respondents have already embarked on the RPA journey and a further 19% of respondents plan to adopt RPA in the next two years". If adoption continues at its current level, RPA will achieve near-universal adoption within the next five years. One reason for such prediction is that RPA has become advanced enough to take over the mundane tasks; prior to that, the technology wasn't quite there.

Let us accept, broader the automation spectrum, more the elimination of manual processes. For organizations to become digitally native it's very much important that an RPA technology should be designed and deployed as an ideal tool to connect multiple legacy systems rapidly and seamlessly such as Big Data, Internet of Things (IoT), cloud, etc. Eventually, it should become a critical part of their value proposition just not for the internal operations but also for the front and back-office functions.

The Addition of "Cognitive Intelligence" to create "Cognitive Automation"

While RPA is expected to act as a first step in the adoption of automation, the rise of new cognitive technologies (which can mimic human intelligence and judgment) is expected to increasingly drive automation by matching the current wave of "Digital Transformation" with the application of AI. In fact, cognitive technologies can be considered as a subset of AI, further grouped into capabilities such as ML, NLP with semantic analysis, machine vision, speech recognition, emotion recognition with sentiment analysis, and optical character recognition.

On August 15, 2018, Deloitte and NICE launched a white paper - "The Future of Operations — Moving Beyond Process Automation" which meticulously covered a futuristic self-service banking scenario that utilizes a myriad of new generation cognitive tools to stay ahead. The paper duly explained the concept called Robotic and Cognitive Automation (R&CA) with a holistic and rich perspective on "how to practically assess and tackle the next technological revolution in artificial intelligence and cognitive automation". Unlike the RPA, given their probabilistic nature, cognitive technologies need to continuously learn from their past actions and evolve more accurate algorithms.

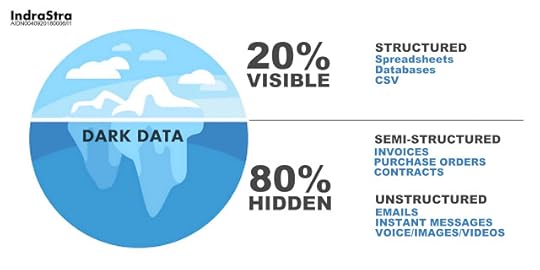

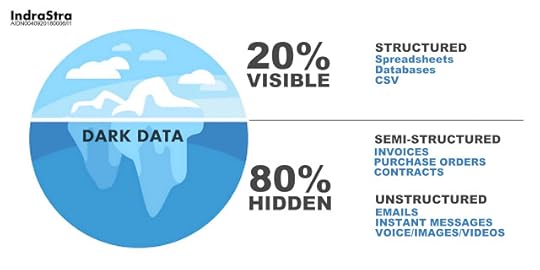

One of the biggest constraints of RPA is that it needs structured data in the form of a spreadsheet, a web form or a database for the robots to work flawlessly. Hence the need for cognitive intelligence (driven by ML/NLP) arises to deal with the unstructured, or semi-structured data and transform it into a structured form, which can then be later processed by the robots.

WorkFusion’s Smart Process Automation (SPA) is one of the classic examples, which is, in turn, paired with RPA to learn from the humans it supports. Using ML-driven data capturing tools, inbuilt quality control, and algorithmic training capabilities, bots shadow human actions and judgment calls to learn routine decision-making processes.

Kindly do note, many advertised AI-powered RPA solutions often turn out to be a basic extension towards ML (Not purely driven by ML as such). Basically, such extensions are quite useful, but they are based on recognition patterns, i.e., having a rule-based dependency. Before selecting any such solution, a due diligence is recommended.

No matter how lucrative cognitive automation seems to be, the first-mover's pursuit in this space may invite risk. The best possible strategy is to test run a set of pilot programs and then evaluate for a smoother downstream implementation. A set of proven pilot results can easily help an organization to formulate a long-term strategy.

The Road Ahead

In a newly published working paper by Lukas Schlogl and Andy Sumner from the think tank, the Center for Global Development (CGD) explained the potential effects of robotics and AI on global labor markets. When automation is used to augment human management, traditional organizational orthodoxies, such as about spans of control, can be challenged. The paper says it’s impossible to know exactly how many jobs will be destroyed or disrupted by new technology. But, authors add, "it’s fairly certain there are going to be significant effects — especially in developing economies, where the labor market is skewed toward work that requires the sort of routine, manual labor that’s so susceptible to automation".

As in the past, technology will not be a purely destructive force like the introduction of Automated Teller Machines (ATMs) pushed down the branch-wise headcounts but at the same time banks got an opportunity to open more branches at the distant corners. In this particular case, new jobs will be created; existing roles will be redefined, and workers will have the opportunity to switch careers. But, the challenge to this generation will be in managing the transition as the individuals who need to retrain for new careers won’t be the young, but middle-aged professionals.

And from the government's end, policy-makers should embrace the opportunity for their economies to benefit from the implementation of cognitive automation and boosting productivity across. To achieve that, they should put in place well-defined policies (flexible, not rigid) to encourage investment and offer market incentives to encourage continued progress and innovation. At the same time, they must evolve and innovate policies (keeping pace with time and evolving technologies) that help current and future workforces adapt to the impact on their respective employment demographic. The dawn of "automation age" has already arrived and it needs an extensive level of social re-engineering which must include revamping the education and training systems, creating substantial income support and pre-defined safety nets, as well as a necessary transitional support for those dislocated or about to be dislocated.

About the Author:

Rahul Guhathakurta (ORCID: 0000-0002-6400-6423) is the founder of IndraStra Global, a strategic analysis, and information services provider.

Cite this Article:

Guhathakurta, R., "Cognitive Automation — Going beyond Rule-based RPA" IndraStra Global, Vol. 04, Issue No: 9 (2018), 0006, http://www.indrastra.com/2018/09/Cognitive-Automation-004-09-2018-0006.html | ISSN 2381-3652

In recent times, organizations across the world from various industry sectors are pushing themselves to become "Digitally Native" by adopting "Digital Transformation" as a foundational pillar for the future — starting with Robotic Process Automation (RPA). And, the primary objectives for the most of them are to achieve speed, accuracy, and reduction in headcounts. The convergence of RPA, artificial intelligence (AI), machine learning (ML), natural language processing (NLP), and cognitive platforms is potentially so disruptive that Klaus Schwab, founder of the World Economic Forum, calls it the "Fourth Industrial Revolution."

At the same time, there is a good share of apocalyptic warnings from various quarters that the advancement of automation (cognitive form) in the workplace will create a "dystopian society". To nullify such warnings, Karen Lachtanski aptly wrote, -"If an argument is to be made against digital transformation, it is that the divide between high-level skills and low-level skills will become wider, with little or no middle ground." In short, she clearly states that there is no time to dwell on it. What going to set the future workforce apart is what we as a part of that workforce are willing to do about it i.e, learn and evolve (or simply perish).

Flowchart Attribute: Sample Automation Architecture for Banking Solution/Financial Services Source: Virtusa

What is Robotic Process Automation (RPA)?

RPA is a basically a software tool that can automate routine tasks/sub-tasks in structured mannered by eliminating human activities such as "copying and pasting data between multiple applications" so that functional/cross-functional teams can focus on more value-adding activities.

In December 2017 survey by Deloitte , "53% of the respondents have already embarked on the RPA journey and a further 19% of respondents plan to adopt RPA in the next two years". If adoption continues at its current level, RPA will achieve near-universal adoption within the next five years. One reason for such prediction is that RPA has become advanced enough to take over the mundane tasks; prior to that, the technology wasn't quite there.

Let us accept, broader the automation spectrum, more the elimination of manual processes. For organizations to become digitally native it's very much important that an RPA technology should be designed and deployed as an ideal tool to connect multiple legacy systems rapidly and seamlessly such as Big Data, Internet of Things (IoT), cloud, etc. Eventually, it should become a critical part of their value proposition just not for the internal operations but also for the front and back-office functions.

The Addition of "Cognitive Intelligence" to create "Cognitive Automation"

While RPA is expected to act as a first step in the adoption of automation, the rise of new cognitive technologies (which can mimic human intelligence and judgment) is expected to increasingly drive automation by matching the current wave of "Digital Transformation" with the application of AI. In fact, cognitive technologies can be considered as a subset of AI, further grouped into capabilities such as ML, NLP with semantic analysis, machine vision, speech recognition, emotion recognition with sentiment analysis, and optical character recognition.

On August 15, 2018, Deloitte and NICE launched a white paper - "The Future of Operations — Moving Beyond Process Automation" which meticulously covered a futuristic self-service banking scenario that utilizes a myriad of new generation cognitive tools to stay ahead. The paper duly explained the concept called Robotic and Cognitive Automation (R&CA) with a holistic and rich perspective on "how to practically assess and tackle the next technological revolution in artificial intelligence and cognitive automation". Unlike the RPA, given their probabilistic nature, cognitive technologies need to continuously learn from their past actions and evolve more accurate algorithms.

One of the biggest constraints of RPA is that it needs structured data in the form of a spreadsheet, a web form or a database for the robots to work flawlessly. Hence the need for cognitive intelligence (driven by ML/NLP) arises to deal with the unstructured, or semi-structured data and transform it into a structured form, which can then be later processed by the robots.

WorkFusion’s Smart Process Automation (SPA) is one of the classic examples, which is, in turn, paired with RPA to learn from the humans it supports. Using ML-driven data capturing tools, inbuilt quality control, and algorithmic training capabilities, bots shadow human actions and judgment calls to learn routine decision-making processes.

Kindly do note, many advertised AI-powered RPA solutions often turn out to be a basic extension towards ML (Not purely driven by ML as such). Basically, such extensions are quite useful, but they are based on recognition patterns, i.e., having a rule-based dependency. Before selecting any such solution, a due diligence is recommended.

No matter how lucrative cognitive automation seems to be, the first-mover's pursuit in this space may invite risk. The best possible strategy is to test run a set of pilot programs and then evaluate for a smoother downstream implementation. A set of proven pilot results can easily help an organization to formulate a long-term strategy.

The Road Ahead

In a newly published working paper by Lukas Schlogl and Andy Sumner from the think tank, the Center for Global Development (CGD) explained the potential effects of robotics and AI on global labor markets. When automation is used to augment human management, traditional organizational orthodoxies, such as about spans of control, can be challenged. The paper says it’s impossible to know exactly how many jobs will be destroyed or disrupted by new technology. But, authors add, "it’s fairly certain there are going to be significant effects — especially in developing economies, where the labor market is skewed toward work that requires the sort of routine, manual labor that’s so susceptible to automation".

As in the past, technology will not be a purely destructive force like the introduction of Automated Teller Machines (ATMs) pushed down the branch-wise headcounts but at the same time banks got an opportunity to open more branches at the distant corners. In this particular case, new jobs will be created; existing roles will be redefined, and workers will have the opportunity to switch careers. But, the challenge to this generation will be in managing the transition as the individuals who need to retrain for new careers won’t be the young, but middle-aged professionals.

And from the government's end, policy-makers should embrace the opportunity for their economies to benefit from the implementation of cognitive automation and boosting productivity across. To achieve that, they should put in place well-defined policies (flexible, not rigid) to encourage investment and offer market incentives to encourage continued progress and innovation. At the same time, they must evolve and innovate policies (keeping pace with time and evolving technologies) that help current and future workforces adapt to the impact on their respective employment demographic. The dawn of "automation age" has already arrived and it needs an extensive level of social re-engineering which must include revamping the education and training systems, creating substantial income support and pre-defined safety nets, as well as a necessary transitional support for those dislocated or about to be dislocated.

About the Author:

Rahul Guhathakurta (ORCID: 0000-0002-6400-6423) is the founder of IndraStra Global, a strategic analysis, and information services provider.

Cite this Article:

Guhathakurta, R., "Cognitive Automation — Going beyond Rule-based RPA" IndraStra Global, Vol. 04, Issue No: 9 (2018), 0006, http://www.indrastra.com/2018/09/Cognitive-Automation-004-09-2018-0006.html | ISSN 2381-3652

Published on September 04, 2018 09:11

August 17, 2017

Digital Supply Chain: Finding Fractions Between the Operational Digits

By Rahul Guhathakurta

In a given set of an environment (controlled or uncontrolled), supply chain risks either amplifies or they simply collude with each other to form a greater risk all-together. "What if", the very environment itself plays a role of catalyst and eventually pushing the outcomes where consequence may be known but cannot be contained? "What if", risk mutates beyond the controlled environment? What if, ambiguity remains radioactive across the decision-making chain? To understand the crux of "What if," one has to look beyond the alternative versions of supply and demand, based on simulations created by the micro-level information blocks, which are extremely critical for the businesses to sustain their own growth in an ever-evolving digital landscape.

Just imagine, having a sudden wake-up moment and emulating a "eureka" with the realization of the existence of "data" within the organization and beyond. In other words, it could end up as an organizational nightmare due to this sudden awareness of relationships with the losses, which were hidden in the first place itself, as the teams were focusing more on top-line targets by taking underbelly hits without knowing the consequences. Well, better late than never.

Let's accept it, "Digitization" of "Supply Chain Management (SCM)" is not at all a new topic. But yes, it did transcend from our subconscious mindset to conscious one very recently. If we look back in a recent timeline, Intel proposed and propagated a concept called - "Inventory in Motion" in the early 2000s [1]. In Intel's vision of inventory in motion, products would be shipped as soon as they are built, before orders are received. Paperwork would be sent electronically to the hub closest to the customer so that it could be put together with products when they arrive at the hub - all electronically.

Generally, it has been found that big and well-invested organizations are often using state-of-the-art technologies to achieve complete end-2-end digital supply chain by constantly redesigning their operating models and go-to-market approaches. They are re-plotting their new routes to customers, decentralizing their in-house activities, and substantially trying to speed up the delivery process by reducing the expected time of arrival (ETA) at customer's end. The overall bottom line is to know the losses beforehand and mitigate them before it becomes too huge for anyone's capability to solve.

What are the Digits?

Primarily, in any given supply chain framework, there are four fundamental "digits" in its dy/dx equation where "deltas" of transformation exist. Those are; identification of inventory item, authentication of the inventory item, location of the inventory item, and automatic data acquisition (ADA) related to that inventory item. [2] If we consider an example of an existing on-hand order, the best way to full-fill it will completely depend on the selection of efficient delivery patterns and matching it with locations based on relevancy.

Also, when it comes to delivery, any well-oiled supply chain application always gives a major thrust to automatic data acquisition (ADA) rather than authentication. In most of the ADA applications, inventory objects such as items, cases, and pallets are tracked automatically and the captured data is used to drive the enterprise applications such as SCM systems, customer relationship management (CRM) systems, and enterprise resource planning (ERP) systems. In the mid-2000s, organizations started experimenting with RFID (Radio Frequency Identification) tags to answer the authentication part of the question which itself quite a "forward-looking" approach at that time, generating greatest opportunity for use of the digital supply network.

And So, what are the fractions we are looking at?

First Fraction: The Technology Landscape

As an industry function, the supply chain management is witnessing a paradigm shift due to ever evolving digital landscape such as the rise in cloud-based technology solutions and creating an Industry 4.0 ecosystem. Such technological approaches are pushing the level of automation a step further by deploying machine learning algorithms, which can teach an inventory management system to predict and forecast order requirement.

Image Attribute: Bosch Transport

Industry 4.0 is defined by interconnectivity - devices within and outside a facility is connected to each other and to human interfaces, providing real-time data from a vast array of sensors. Paired with advanced analytics and machine learning, this ecosystem of sensors, devices, and humans is incredibly powerful. No wonder, technology is acting as a buffer against market volatility as it enables the organization to scale up or down the level of services and at the same time provides necessary customizations to support an organization's rapid expansion plan.

Second Fraction: The Robust Data Harvesting & Mining

The absolute perfect data is a myth. A solid data consistency is the need of the hour. So, before taking a leap of faith, it's utterly important for an organization to have a crystal clear "enterprise-level data strategy". The rise in the sheer volume of data churned by single/multiple supply chains and their newly formed digital reporting and analytics system is not only overwhelming — it has the potential to harm by adding a counterproductive level of complexity that leads to chaos [3]. On top of that, the rise of multiple incompatible data analysis tools, finding a way to obtain a unified enterprise view of the disparate data in their systems are always going to remain one of the added challenges.

A focused approach to the handling of data helps organizations avoid going stray from the path by following non-causal correlations that can emerge from large data sets. And it makes ongoing and future analysis and interpretation more manageable and, thus, better able to consistently provide the business insights companies need to fuel their digital business models and the supply chains that support them.

Third Fraction: The Definitive Interpretations & Inquisitive Decision-makings

Data are ideas, communique about reality - not the reality itself. So, when designing a supply chain network map, the backbone of any business, one needs to read the data and its analytics right or it will turn out as an Achilles' heel.

From a general point of view, there are at least two overriding requirements for an intelligent computer-based decision-making environment. The first requirement relates to the representation of information within the environment. The software must have some level of understanding of the information context that underlies the interactions of the human user with the environment. This is fundamental to any meaningful human-computer interaction that is akin to a partnership. The level to which this understanding can be elevated will largely determine the assistance capabilities and essentially the value of the software environment to the human user.

The second requirement is related to the need for collaboration. In a broad sense, this includes not only the ability to interact with human stakeholders who play a role in the supply-chain, such as planning and management personnel, vendors, remote distribution centers, shippers, and customs officials but also non-human sources of information and capabilities. All of these interactions between human participants in the logistic processes, data sources, and software-based problem-solving capabilities, must be able to be performed seamlessly without the user having to be concerned about access protocols, data formats, or system interoperability issues.

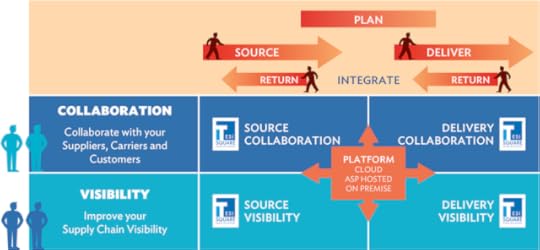

So, when it comes to select a "decision support framework" to support multiple supply chain data sources, one should refer to industry-approved SCOR Model [5]. It is based on three major principles: process modeling/re-engineering, measuring performance, and best practices. There are five distinct process-modeling building blocks to the SCOR model: plan, source, make, deliver, and return. However, SCOR model itself is a hierarchical model which integrates supply chain by covering all interactions with customers from incoming order to incoming payments and all material flow, the production processes as well as all interactions with the market from resource delivery from the supplier to the delivery to the customer.

Infographics Attribute: TESISQUARE solutions positioning within the SCOR® model covering the entire Supply Chain / Source: TESISQUARE Official Website

Fourth Fraction: The Predictive Analytics

The basic role of any data analytics platform is to enhance the control points across the supply chain by improving the margins and increasing the revenues by managing the working capital in an optimum way. To mitigate the divergences in the chain, it's better to deploy one (over the top) data analytics platform which will act as a silo and aggregate the data from the multiple sources. And, with growth in advanced machine learning technologies based on Natural Language Processing (NLP), siloed data can be automated, aligned/collated, and visualized at various hierarchical levels of an organization.

In real-time, targets can be set at different nodes of supply chain channels through the insights generated via predictive analytics. These targets may form a part of the management-by-objectives in an organization, along with pre-defined tolerance factors. Now, when an actual value exceeds one of these tolerances, a corrective trigger will get fired seamlessly across the platform.[6]

One such recommended set of tools comes from IBM's stable - the IBM Predictive Operational Analytics (based on SPSS and Cognos)[7] - when it is collectively deployed, it can help supply chain executives to determine the correct inventory levels for products and materials at virtually all stages along the supply chain. These solutions can help organizations balance the tradeoffs between carrying costs and customer service levels—and between production volume and capital reserves.

Consecutively, by analyzing the data from ERP systems and CRM systems, plus logistics information from factory floors, distribution centers, and retailers, organizations can gain the insight they need to make better, smarter decisions and compete more successfully.

Conclusion:

As we know, mathematically, fractions can be proper or improper. Proper fractions are those whose numerator is less than the denominator, therefore, its value is between zero and one. Moreover, improper fractions are those whose numerator is greater than the denominator, that is, its value is greater than 1. So, it's critically important for a supply chain team to know these fractions in "proper" manner so that they can derive maximum value from the investments and at the same time, the team should also work to convert the "Improper" fractions into mixed fractions and vice versa as per the need - by having a clear understanding of the digital aspects of a supply chain network with regards to the conversion of data into actionable insights.

About the Author:

Rahul Guhathakurta , Founder/Publisher at IndraStra Global. He tweets at @rahulogy.

Cite this Article:

Guhathakurta, R. "Digital Supply Chain: Finding Fractions Between the Operational Digits", IndraStra Global Vol. 003, Issue No: 08 (2017) 0013, http://www.indrastra.com/2017/08/Digital-Supply-Chain-Finding-Fractions-Between-the-Operational-Digits-003-08-2017-0013.html | ISSN 2381-3652

References:

[1] Leach, P.T., (2004), "Inventory in motion", JOC.com, http://www.joc.com/inventory-motion_2...

[2] Asif, Z., and Mandviwalla, M., (2005), "Integrating the Supply Chain with RFID: A Technical and Business Analysis," Communications of the Association for Information Systems: Vol. 15, Article 24. Available at: http://aisel.aisnet.org/cais/vol15/is...

[3] Ernst & Young (2016), "Top of mind | Digital supply chain: it’s all about that data" http://www.ey.com/Publication/vwLUAss...

[4] Phol, J. (2011) "An Intelligent Supply Chain Planning and Execution Environment", California Polytechnic State University (Cal Poly), San Luis Obispo, California, IS11-Pohl-Focus-Paper

[5] Hudson, S., (2004), "The SCOR Model for Supply Chain Strategic Decisions", Poole College of Management, NC State University https://scm.ncsu.edu/scm-articles/art...

[6] Guhathakurta, R. (2016), "Is predictive analytics in unified commerce the future of retail?", Yourstory.com, https://yourstory.com/2016/08/unified...

[7] IBM Predictive Operational Analytics, https://www-01.ibm.com/software/analy...

In a given set of an environment (controlled or uncontrolled), supply chain risks either amplifies or they simply collude with each other to form a greater risk all-together. "What if", the very environment itself plays a role of catalyst and eventually pushing the outcomes where consequence may be known but cannot be contained? "What if", risk mutates beyond the controlled environment? What if, ambiguity remains radioactive across the decision-making chain? To understand the crux of "What if," one has to look beyond the alternative versions of supply and demand, based on simulations created by the micro-level information blocks, which are extremely critical for the businesses to sustain their own growth in an ever-evolving digital landscape.

Just imagine, having a sudden wake-up moment and emulating a "eureka" with the realization of the existence of "data" within the organization and beyond. In other words, it could end up as an organizational nightmare due to this sudden awareness of relationships with the losses, which were hidden in the first place itself, as the teams were focusing more on top-line targets by taking underbelly hits without knowing the consequences. Well, better late than never.

Let's accept it, "Digitization" of "Supply Chain Management (SCM)" is not at all a new topic. But yes, it did transcend from our subconscious mindset to conscious one very recently. If we look back in a recent timeline, Intel proposed and propagated a concept called - "Inventory in Motion" in the early 2000s [1]. In Intel's vision of inventory in motion, products would be shipped as soon as they are built, before orders are received. Paperwork would be sent electronically to the hub closest to the customer so that it could be put together with products when they arrive at the hub - all electronically.

Generally, it has been found that big and well-invested organizations are often using state-of-the-art technologies to achieve complete end-2-end digital supply chain by constantly redesigning their operating models and go-to-market approaches. They are re-plotting their new routes to customers, decentralizing their in-house activities, and substantially trying to speed up the delivery process by reducing the expected time of arrival (ETA) at customer's end. The overall bottom line is to know the losses beforehand and mitigate them before it becomes too huge for anyone's capability to solve.

What are the Digits?

Primarily, in any given supply chain framework, there are four fundamental "digits" in its dy/dx equation where "deltas" of transformation exist. Those are; identification of inventory item, authentication of the inventory item, location of the inventory item, and automatic data acquisition (ADA) related to that inventory item. [2] If we consider an example of an existing on-hand order, the best way to full-fill it will completely depend on the selection of efficient delivery patterns and matching it with locations based on relevancy.

Also, when it comes to delivery, any well-oiled supply chain application always gives a major thrust to automatic data acquisition (ADA) rather than authentication. In most of the ADA applications, inventory objects such as items, cases, and pallets are tracked automatically and the captured data is used to drive the enterprise applications such as SCM systems, customer relationship management (CRM) systems, and enterprise resource planning (ERP) systems. In the mid-2000s, organizations started experimenting with RFID (Radio Frequency Identification) tags to answer the authentication part of the question which itself quite a "forward-looking" approach at that time, generating greatest opportunity for use of the digital supply network.

And So, what are the fractions we are looking at?

First Fraction: The Technology Landscape

As an industry function, the supply chain management is witnessing a paradigm shift due to ever evolving digital landscape such as the rise in cloud-based technology solutions and creating an Industry 4.0 ecosystem. Such technological approaches are pushing the level of automation a step further by deploying machine learning algorithms, which can teach an inventory management system to predict and forecast order requirement.

Image Attribute: Bosch Transport

Industry 4.0 is defined by interconnectivity - devices within and outside a facility is connected to each other and to human interfaces, providing real-time data from a vast array of sensors. Paired with advanced analytics and machine learning, this ecosystem of sensors, devices, and humans is incredibly powerful. No wonder, technology is acting as a buffer against market volatility as it enables the organization to scale up or down the level of services and at the same time provides necessary customizations to support an organization's rapid expansion plan.

Second Fraction: The Robust Data Harvesting & Mining

The absolute perfect data is a myth. A solid data consistency is the need of the hour. So, before taking a leap of faith, it's utterly important for an organization to have a crystal clear "enterprise-level data strategy". The rise in the sheer volume of data churned by single/multiple supply chains and their newly formed digital reporting and analytics system is not only overwhelming — it has the potential to harm by adding a counterproductive level of complexity that leads to chaos [3]. On top of that, the rise of multiple incompatible data analysis tools, finding a way to obtain a unified enterprise view of the disparate data in their systems are always going to remain one of the added challenges.

A focused approach to the handling of data helps organizations avoid going stray from the path by following non-causal correlations that can emerge from large data sets. And it makes ongoing and future analysis and interpretation more manageable and, thus, better able to consistently provide the business insights companies need to fuel their digital business models and the supply chains that support them.

Third Fraction: The Definitive Interpretations & Inquisitive Decision-makings

Data are ideas, communique about reality - not the reality itself. So, when designing a supply chain network map, the backbone of any business, one needs to read the data and its analytics right or it will turn out as an Achilles' heel.

From a general point of view, there are at least two overriding requirements for an intelligent computer-based decision-making environment. The first requirement relates to the representation of information within the environment. The software must have some level of understanding of the information context that underlies the interactions of the human user with the environment. This is fundamental to any meaningful human-computer interaction that is akin to a partnership. The level to which this understanding can be elevated will largely determine the assistance capabilities and essentially the value of the software environment to the human user.

The second requirement is related to the need for collaboration. In a broad sense, this includes not only the ability to interact with human stakeholders who play a role in the supply-chain, such as planning and management personnel, vendors, remote distribution centers, shippers, and customs officials but also non-human sources of information and capabilities. All of these interactions between human participants in the logistic processes, data sources, and software-based problem-solving capabilities, must be able to be performed seamlessly without the user having to be concerned about access protocols, data formats, or system interoperability issues.

So, when it comes to select a "decision support framework" to support multiple supply chain data sources, one should refer to industry-approved SCOR Model [5]. It is based on three major principles: process modeling/re-engineering, measuring performance, and best practices. There are five distinct process-modeling building blocks to the SCOR model: plan, source, make, deliver, and return. However, SCOR model itself is a hierarchical model which integrates supply chain by covering all interactions with customers from incoming order to incoming payments and all material flow, the production processes as well as all interactions with the market from resource delivery from the supplier to the delivery to the customer.

Infographics Attribute: TESISQUARE solutions positioning within the SCOR® model covering the entire Supply Chain / Source: TESISQUARE Official Website

Fourth Fraction: The Predictive Analytics

The basic role of any data analytics platform is to enhance the control points across the supply chain by improving the margins and increasing the revenues by managing the working capital in an optimum way. To mitigate the divergences in the chain, it's better to deploy one (over the top) data analytics platform which will act as a silo and aggregate the data from the multiple sources. And, with growth in advanced machine learning technologies based on Natural Language Processing (NLP), siloed data can be automated, aligned/collated, and visualized at various hierarchical levels of an organization.

In real-time, targets can be set at different nodes of supply chain channels through the insights generated via predictive analytics. These targets may form a part of the management-by-objectives in an organization, along with pre-defined tolerance factors. Now, when an actual value exceeds one of these tolerances, a corrective trigger will get fired seamlessly across the platform.[6]

One such recommended set of tools comes from IBM's stable - the IBM Predictive Operational Analytics (based on SPSS and Cognos)[7] - when it is collectively deployed, it can help supply chain executives to determine the correct inventory levels for products and materials at virtually all stages along the supply chain. These solutions can help organizations balance the tradeoffs between carrying costs and customer service levels—and between production volume and capital reserves.

Consecutively, by analyzing the data from ERP systems and CRM systems, plus logistics information from factory floors, distribution centers, and retailers, organizations can gain the insight they need to make better, smarter decisions and compete more successfully.

Conclusion:

As we know, mathematically, fractions can be proper or improper. Proper fractions are those whose numerator is less than the denominator, therefore, its value is between zero and one. Moreover, improper fractions are those whose numerator is greater than the denominator, that is, its value is greater than 1. So, it's critically important for a supply chain team to know these fractions in "proper" manner so that they can derive maximum value from the investments and at the same time, the team should also work to convert the "Improper" fractions into mixed fractions and vice versa as per the need - by having a clear understanding of the digital aspects of a supply chain network with regards to the conversion of data into actionable insights.

About the Author:

Rahul Guhathakurta , Founder/Publisher at IndraStra Global. He tweets at @rahulogy.

Cite this Article:

Guhathakurta, R. "Digital Supply Chain: Finding Fractions Between the Operational Digits", IndraStra Global Vol. 003, Issue No: 08 (2017) 0013, http://www.indrastra.com/2017/08/Digital-Supply-Chain-Finding-Fractions-Between-the-Operational-Digits-003-08-2017-0013.html | ISSN 2381-3652

References:

[1] Leach, P.T., (2004), "Inventory in motion", JOC.com, http://www.joc.com/inventory-motion_2...

[2] Asif, Z., and Mandviwalla, M., (2005), "Integrating the Supply Chain with RFID: A Technical and Business Analysis," Communications of the Association for Information Systems: Vol. 15, Article 24. Available at: http://aisel.aisnet.org/cais/vol15/is...

[3] Ernst & Young (2016), "Top of mind | Digital supply chain: it’s all about that data" http://www.ey.com/Publication/vwLUAss...

[4] Phol, J. (2011) "An Intelligent Supply Chain Planning and Execution Environment", California Polytechnic State University (Cal Poly), San Luis Obispo, California, IS11-Pohl-Focus-Paper

[5] Hudson, S., (2004), "The SCOR Model for Supply Chain Strategic Decisions", Poole College of Management, NC State University https://scm.ncsu.edu/scm-articles/art...

[6] Guhathakurta, R. (2016), "Is predictive analytics in unified commerce the future of retail?", Yourstory.com, https://yourstory.com/2016/08/unified...

[7] IBM Predictive Operational Analytics, https://www-01.ibm.com/software/analy...

Published on August 17, 2017 07:08

May 29, 2017

B&E | Critical Aspects in Designing an Omnichannel Customer Experiences

By Rahul Guhathakurta

Image Attribute: Pixabay.com

Across the world, retailers are facing cut-throat competition, not only during selling but also during retaining the same customer to resell their current category of products along with other categories. There is no doubt that, the "digital demand" drives omnichannel in the first place, and omnichannel as a product of digital demand creates expectations in the consumer to that extent that practically anything they imagine is deliverable. So they use omnichannel retailing through all physical channels (offline) and digital channels (online), which in turn offers a seamless, innovative and unified customer experience.

After years of cautious engagement in the online sales channel, retailers are fully committed to building requisite capabilities for the online segment of their business. Many of them report making long-term investments in acquiring powerful, full-featured technology platforms as well as expanding their network of distribution centers (DCs) and order fulfillment facilities. This strategic commitment to the online channel by store-based retailers comes at a time when their mammoth competitor in the online channel, Amazon, continues to make inroads into the retail markets.

Across the retail industry, the supply chain executives are now focusing on leveraging technology and infrastructure investments made in prior years, to gain a much needed competitive edge. The next step for them is to review and upgrade business processes around the new technology and fulfillment capabilities. These restructuring efforts are not only directed at business processes but at organizational and human resource aspects of change management as well.

What is Omnichannel Retailing?

Multichannel retailing or Omnichannel retailing is the use of a variety of channels in a customer's shopping experience including research before a purchase. Such channels include retail stores, online stores, mobile stores, mobile app stores, telephone sales and any other method of transacting with a customer. Transacting includes browsing, buying, returning as well as pre-sale and after-sale service.

The omnichannel is often said to be dictated by systems and processes, but in fact, it is the customer that dictates the route they take during transact. Systems and processes within retail simply facilitate the customer journey to transact and be served, it is multiple channels a very complicated path to establish for successful functionality with the inbuilt flexibility to cater different customer through distribution centers (DCs).

Supply Chain Integration for Omnichannel

Internal supply chain integration is undertaken for joining otherwise separate activities such as purchasing, warehousing, transportation, and distribution as well as customer service within a single enterprise. Presently companies are expanding systems outside the firm’s boundaries to identify higher value opportunities through collaborating with related supply chain partners, External integration, based on information sharing, helped building systems and coordination dimension among companies to improve performance.

Demand Planning

Historically, retailers have forecasted demand for in-store and online channels separately. In an effort to improve demand planning, retail supply chain executives are focused on understanding the extensive demand variation within and between channels. They are also trying to better identify where demand occurs to ensure inventory availability when and where customers need it. This effectively means that correctly forecasting aggregate demand is no longer sufficient. Retailers must also be able to accurately predict the origin of demand (region, store, and channel). For this reason, many executives indicated that they need demand planning at a finer level of detail (item level, store level, channel level). With the proportion of online sales increasing, retailers have a need to establish a single, integrated demand planning process.

Integrated demand planning requires a shift away from the top-down demand forecasting approach currently in use. Instead, a bottom-up approach focused on aggregating demand at the store level and by sales channel is needed.

Integration of channels into demand planning will help retailers expose all inventory – in-store and in the DC – to omnichannel customers. Implementation of this strategy will require retailers to acquire greater analytics and technology firepower. These tools must be capable of handling the vast data requirements of planning at the product category level in stores and across different sales channels.

Word of Caution:

The role of demand planning is not for the faint of heart or the analytical lightweight. Demand planning in a complex omnichannel retail world calls for new innovative approaches, heavy data crunching, and analyst finesse. Smart retailers are responding by establishing cross-functional teams of the merchant, supply chain, and store operations professionals who develop granular-level demand plans covering multiple demand streams and fulfillment nodes. They must couple these plans with innovative store replenishment and delivery processes to respond to changing demand dynamics in this complex planning environment.

Rise in Store-Based Fulfillment Consistency

Fast forward to 2018 and Retailers clearly recognize that store inventory can effectively support demand from multiple channels. As more omnichannel orders are directed to stores, effective strategies must be established. The need for greater customer service for online orders must be balanced against preserving the shopping experience of the in-store customer.

Numerous retailers are following a hub store strategy, and this method is expected to grow significantly over the next 3-5 years. This approach consolidates store fulfillment inside larger and/or centrally located stores rather than establishing fulfillment capability across the entire store network. The hub store may keep larger inventories across the board or have extra backroom space to support picking of high volume items.

Benefits of the hub store approach include reduced inventory management complexity, reduced associate training, and consistent quality of order preparation and customer service. A downside of this approach is that the customer desiring in-store pick-up may be directed to a location that is not the closest, most convenient store.

Omnichannel fulfillment has evolved from a primarily DC-based model to one that leverages all inventory nodes across the network, especially the store. For the same day / next day delivery being demanded by omnichannel, stores often provide the best fulfillment option for retailers. While there are still kinks to be worked out in the store fulfillment process, we believe retailers are moving aggressively toward a model that removes orders from the DC network and places a large percentage of these orders in stores.

Conclusion:

It is evident any type of study cannot offer one right solution for a retailer to develop their omnichannel customer experience. The customer behavior is customer-specific and company strategy should lead the investment decisions to finally lead to the supply chain decisions and offered service level. To plan a well-structured supply chain, retail managers have to understand the customer behavior and all the phases of the customer buying process. Data brought in by the different digital channels is in an important role in the creation of this understanding. In contrast, to offer the best possible customer experience, managers have to make strategic decisions over the supply chain options and control all the factors affecting the omnichannel experience. The parts of the supply chain process that require manual labor will always be the bottlenecks of the service and should be carefully controlled. Technological innovations can bring advancements in the supply chain process and thus cost savings but the investment decision is one of the most important trade-off decisions managers face in the omnichannel retail development.

About the Author:

Rahul Guhathakurta is the founder of IndraStra Global, a strategic analysis, and information services provider. He distributes his time between New York and Ahmedabad.

Cite this Article:

Guhathakurta, R. "B&E | Critical Aspects in Designing an Omnichannel Customer Experiences", IndraStra Global Vol. 03, Issue No: 5 (2017) 0059, http://www.indrastra.com/2017/05/BE-Critical-Aspects-of-Designing-an-Omnichannel-Customer-Experiences-003-05-2017-0059.html | ISSN 2381-3652

Image Attribute: Pixabay.com

Across the world, retailers are facing cut-throat competition, not only during selling but also during retaining the same customer to resell their current category of products along with other categories. There is no doubt that, the "digital demand" drives omnichannel in the first place, and omnichannel as a product of digital demand creates expectations in the consumer to that extent that practically anything they imagine is deliverable. So they use omnichannel retailing through all physical channels (offline) and digital channels (online), which in turn offers a seamless, innovative and unified customer experience.

After years of cautious engagement in the online sales channel, retailers are fully committed to building requisite capabilities for the online segment of their business. Many of them report making long-term investments in acquiring powerful, full-featured technology platforms as well as expanding their network of distribution centers (DCs) and order fulfillment facilities. This strategic commitment to the online channel by store-based retailers comes at a time when their mammoth competitor in the online channel, Amazon, continues to make inroads into the retail markets.

Across the retail industry, the supply chain executives are now focusing on leveraging technology and infrastructure investments made in prior years, to gain a much needed competitive edge. The next step for them is to review and upgrade business processes around the new technology and fulfillment capabilities. These restructuring efforts are not only directed at business processes but at organizational and human resource aspects of change management as well.

What is Omnichannel Retailing?

Multichannel retailing or Omnichannel retailing is the use of a variety of channels in a customer's shopping experience including research before a purchase. Such channels include retail stores, online stores, mobile stores, mobile app stores, telephone sales and any other method of transacting with a customer. Transacting includes browsing, buying, returning as well as pre-sale and after-sale service.

The omnichannel is often said to be dictated by systems and processes, but in fact, it is the customer that dictates the route they take during transact. Systems and processes within retail simply facilitate the customer journey to transact and be served, it is multiple channels a very complicated path to establish for successful functionality with the inbuilt flexibility to cater different customer through distribution centers (DCs).

Supply Chain Integration for Omnichannel

Internal supply chain integration is undertaken for joining otherwise separate activities such as purchasing, warehousing, transportation, and distribution as well as customer service within a single enterprise. Presently companies are expanding systems outside the firm’s boundaries to identify higher value opportunities through collaborating with related supply chain partners, External integration, based on information sharing, helped building systems and coordination dimension among companies to improve performance.

Demand Planning

Historically, retailers have forecasted demand for in-store and online channels separately. In an effort to improve demand planning, retail supply chain executives are focused on understanding the extensive demand variation within and between channels. They are also trying to better identify where demand occurs to ensure inventory availability when and where customers need it. This effectively means that correctly forecasting aggregate demand is no longer sufficient. Retailers must also be able to accurately predict the origin of demand (region, store, and channel). For this reason, many executives indicated that they need demand planning at a finer level of detail (item level, store level, channel level). With the proportion of online sales increasing, retailers have a need to establish a single, integrated demand planning process.

Integrated demand planning requires a shift away from the top-down demand forecasting approach currently in use. Instead, a bottom-up approach focused on aggregating demand at the store level and by sales channel is needed.

Integration of channels into demand planning will help retailers expose all inventory – in-store and in the DC – to omnichannel customers. Implementation of this strategy will require retailers to acquire greater analytics and technology firepower. These tools must be capable of handling the vast data requirements of planning at the product category level in stores and across different sales channels.

Word of Caution:

The role of demand planning is not for the faint of heart or the analytical lightweight. Demand planning in a complex omnichannel retail world calls for new innovative approaches, heavy data crunching, and analyst finesse. Smart retailers are responding by establishing cross-functional teams of the merchant, supply chain, and store operations professionals who develop granular-level demand plans covering multiple demand streams and fulfillment nodes. They must couple these plans with innovative store replenishment and delivery processes to respond to changing demand dynamics in this complex planning environment.

Rise in Store-Based Fulfillment Consistency

Fast forward to 2018 and Retailers clearly recognize that store inventory can effectively support demand from multiple channels. As more omnichannel orders are directed to stores, effective strategies must be established. The need for greater customer service for online orders must be balanced against preserving the shopping experience of the in-store customer.

Numerous retailers are following a hub store strategy, and this method is expected to grow significantly over the next 3-5 years. This approach consolidates store fulfillment inside larger and/or centrally located stores rather than establishing fulfillment capability across the entire store network. The hub store may keep larger inventories across the board or have extra backroom space to support picking of high volume items.

Benefits of the hub store approach include reduced inventory management complexity, reduced associate training, and consistent quality of order preparation and customer service. A downside of this approach is that the customer desiring in-store pick-up may be directed to a location that is not the closest, most convenient store.

Omnichannel fulfillment has evolved from a primarily DC-based model to one that leverages all inventory nodes across the network, especially the store. For the same day / next day delivery being demanded by omnichannel, stores often provide the best fulfillment option for retailers. While there are still kinks to be worked out in the store fulfillment process, we believe retailers are moving aggressively toward a model that removes orders from the DC network and places a large percentage of these orders in stores.

Conclusion:

It is evident any type of study cannot offer one right solution for a retailer to develop their omnichannel customer experience. The customer behavior is customer-specific and company strategy should lead the investment decisions to finally lead to the supply chain decisions and offered service level. To plan a well-structured supply chain, retail managers have to understand the customer behavior and all the phases of the customer buying process. Data brought in by the different digital channels is in an important role in the creation of this understanding. In contrast, to offer the best possible customer experience, managers have to make strategic decisions over the supply chain options and control all the factors affecting the omnichannel experience. The parts of the supply chain process that require manual labor will always be the bottlenecks of the service and should be carefully controlled. Technological innovations can bring advancements in the supply chain process and thus cost savings but the investment decision is one of the most important trade-off decisions managers face in the omnichannel retail development.

About the Author:

Rahul Guhathakurta is the founder of IndraStra Global, a strategic analysis, and information services provider. He distributes his time between New York and Ahmedabad.

Cite this Article:

Guhathakurta, R. "B&E | Critical Aspects in Designing an Omnichannel Customer Experiences", IndraStra Global Vol. 03, Issue No: 5 (2017) 0059, http://www.indrastra.com/2017/05/BE-Critical-Aspects-of-Designing-an-Omnichannel-Customer-Experiences-003-05-2017-0059.html | ISSN 2381-3652

Published on May 29, 2017 23:50

March 7, 2015

History never forgets and forgives, so tread wisely!

Chanakya“The earth is supported by the power of truth; it is the power of truth that makes the sun shine and the winds blow; indeed all things rest upon truth.” – Chanakya, B.C 350

Chanakya“The earth is supported by the power of truth; it is the power of truth that makes the sun shine and the winds blow; indeed all things rest upon truth.” – Chanakya, B.C 350 By Rahul Guhathakurta

In today’s world, there is a marginal difference between right and wrong. As time proceeds, the history gets diluted with the writings of winners and apathy of losers. Eventually, we become a bunch of pathological liars driven by propaganda supporting the collection of lies constituted by those who want us to have a distorted belief at the first place.

The nations were built on the foundation of equality, liberty, and freedom. Our forefathers sacrificed their lives to fetch the fruits of independence, not for themselves but for us. They used information to add needed propulsion for achieving freedom and they used intellectuality to justify the need for our freedom based on unity. However, we as a "humankind" have failed at every level of integration, in using such wisdom which we had gained but sadly we lost.

The call is about how we perceive things in the right direction with right orientation and decide upon to act in a right framework of time. IndraStra is one small step towards it on a liberal note to bring all the intellectuals who can and who will demonstrate the existence of truth over the lies in a subtle manner and by respecting the laws of the land.

We are here to raise questions for your answers, so join us to make a difference.

Published on March 07, 2015 23:03