Lean for the Holidays

Over the past few days, I’ve received a number of clever holiday and Lean-themed videos, maps, and stories that I thought I’d share. I’m sure there are many more out there, so please feel free to share in the comments area. Enjoy!

Will Farrell, Quality Inspector?

This is a funny scene from the movie Elf where Will Ferrell performs quality control for jack-in-the-boxes:

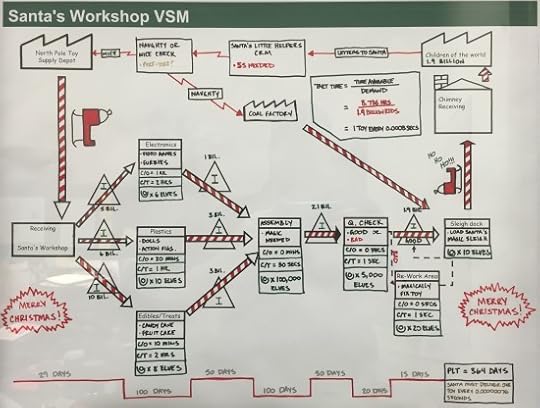

Santa’s Value Stream

Here’s a clever value stream map, created by Jordan Kempler at TMAC:

Santa Believes in Kaizen!

And who knew that Santa was so Lean-savvy? Enjoy this story written by one of our subscribers, Tom Gardzinski.

With the total days of the year fixed and global population skyrocketing over the past 150 years, Santa had to figure out how to do more within the same time period. So Santa turned to continuous improvement. Santa and his elves learned about the eight operational wastes and the problem-solving methodology, Plan, Do, Study and Adjust (PDSA).

One problem they wanted to avoid was the toy shortage that they had experienced in 2011. Retailers were holding less inventory as a precautionary measure to avoid the losses they experienced a year earlier due to the recession and a slower-than-normal shopping season. But what Santa and the elves discovered was that could be traced back to excessive lead times at the largest toy manufacturing on the planet, Santa’s own workshop. With customers dissatisfied because they were not receiving product or had to settle for cheap knock-offs, Santa couldn’t ignore this problem. So he organized a Kaizen Event with a team of elves to discover how to reduce lead time through the elimination of non-value-added activities. The team discovered that they spent 50% of the overall lead time just getting the Christmas list orders to the production floor.

First, they eliminated excessive approvals, which shortened lead time by a few days. Then, by removing the outdated mailroom and upgrading to a sophisticated mail scanning system, Santa’s Workshop was able to transfer the mailroom staff onto the toy production floor to help wrap the toys as they came off the production line. The team started to realize how removing non-value added waste is critical in fulfilling children’s wish lists. This new mail scanning system helped reduce 5 of the 8 wastes; overproduction, over-processing, waiting, inventory, motion, and under-utilization (lost creativity) of people. (Images used by permission by Jerome Holst, Enchanted America and Candice Russell, Pitney Bowes.)

Another waste that the team discovered was the amount of batch processing that was in place. Children had been sending their Christmas wish lists only three weeks before Santa had to saddle up! To level external demand, Santa offered incentives to all children who sent their wish lists by November 15 of each year. Spreading the work out over a longer time period allowed for less overtime which meant happier and healthier elves! The children were also thrilled because they received bonus gifts on Christmas morning as a reward for sending in their wish list early.

The above are just two CI events that have been highlighted from the last five years at Santa’s Workshop, and they’re still working on improvements to keep up with growing toy demands!

I hope you’ve enjoyed a little Lean humor and holiday cheer! May you and your family have a joyful Christmas, Hannukah, Kwanza, or whatever you celebrate.

And may 2016 bring you:

Outstanding health, happiness, and prosperity

Intellectual, emotional and spiritual fulfillment at work

Deepening humility, curiosity, and respect for humankind

Continued success in developing proficiency in leading improvement

And may we all experience greater peace on earth and an end to senseless violence.