Evelyn Tan's Blog

August 14, 2023

A collection of my Linkedin Post on how different department impact product quality

June 2, 2023

The Dance of Quality: Unveiling the Thrilling Collaboration Behind Your Favorite Products

In today's fast-paced world, the journey from raw materials to the finished products we love is no longer a one-person show. It's a thrilling collaboration that involves a network of manufacturing facilities, forming what we call the product supply chain. This chain links the suppliers of raw materials to the eager hands of consumers, passing through various tiers of suppliers along the way.

Imagine this: every manufacturer depends on their upstream suppliers for essential parts. It's like a well-choreographed dance, where the quality of those parts determines the quality of the final product. Nobody wants to turn shoddy materials into a masterpiece, right? That's why manufacturers must ensure they receive consistently top-notch parts from their suppliers. It's a crucial step because, once the product reaches the expert hands of the original equipment manufacturer (OEM) or original design manufacturer (ODM), there's little room for adjustments.

To master this intricate dance, OEMs must establish robust supplier chain management programs. These programs are the secret sauce that ensures their primary and subsequent suppliers produce parts with precision and adhere to the required specifications. We're talking about minimizing any variations that might compromise the quality of the end product.

Within this supplier chain management realm, there are three essential components: supplier performance management, supplier quality management, and supplier chain risk management. But let's focus on one superhero today: supplier quality management. It's the unsung hero that ensures you, the consumer, get consistently exceptional products.

So, the next time you hold a high-quality product in your hands, remember the thrilling collaboration behind its creation, powered by the magic of supplier quality management.

May 20, 2023

Achieving Quality through Effective Sourcing Strategy

Quality is an essential aspect of any organization's success. It is attained through meticulous design, careful planning, and meticulous execution throughout the product development process, with contributions from every individual within the organization. This principle holds true even for the procurement process and the sourcing strategy employed by an organization, as it significantly impacts the quality of the materials supplied by suppliers.

The sourcing strategy should be initiated before selecting suppliers to provide materials or parts for the manufacturing line. The procurement department should take the lead in steering the sourcing strategy, involving a cross-functional team comprising members from quality, process, engineering, development, and finance. The procurement lead within the organization must establish a robust supplier sourcing strategy, encompassing a step-by-step approach from understanding the business requirements to analyzing market segments, selecting suppliers, and monitoring their performance.

Before finalizing a supplier, it is crucial for a company to review its internal material requests and gather relevant information, including:

📑Categorization of the desired products (mechanical, electrical, etc.).

💲Total expenditure in the market for the materials, spend analysis for the specific product category, identification of competitors, and potential suppliers.

🎯Specification requirements for the materials in question.

Considering these points provides an overview of the supplier market, aiding in the establishment of future partnerships with suppliers. It is vital to understand one's own organization before seeking to understand potential suppliers.

The subsequent step involves conducting a supply market analysis to identify the key players in the market and comprehend the overall economics, business dynamics, and industry trends influencing the market and supplier profiling.

Once the key players are identified, a sourcing strategy can be developed, encompassing various aspects such as supplier development programs for product and process improvement, and the allocation of volume based on the total cost of ownership. Total cost of ownership goes beyond the direct material cost and incorporates the potential costs associated with poor quality, such as servicing and customer dissatisfaction. Unfortunately, many organizations fail to grasp this concept and merely award business to the supplier with the lowest price.

After formulating the sourcing strategy, the organization moves on to supplier selection. While various factors, including the supplier's financial status, technology roadmap, and cost efficiency, should be considered during supplier selection, this article focuses primarily on assessing supplier quality, as it directly impacts the overall quality of the parts.

The significance of the sourcing strategy lies in its ability to determine an organization's capacity to source the highest quality parts from the market at the best total cost of ownership. A well-crafted sourcing strategy serves as an example of quality planning, highlighting the procurement department's impact on ensuring quality. In the absence of a sound sourcing strategy or when poor sourcing decisions are made, managing supplier quality downstream becomes an immensely challenging task.

By recognizing the importance of a comprehensive sourcing strategy, organizations can enhance their ability to source high-quality parts while considering the overall cost implications. Sourcing strategy serves as a critical link between procurement and quality, ensuring a seamless flow of quality throughout the supply chain.

September 2, 2022

What does supplier quality engineer do?

Supplier quality engineers or managers (SQE/SQM) are in a powerful position to drive supplier quality to the highest level possible and this authority is even higher than the organization internal quality department. Remember the customer is always right. They should learn on how to manage the whole supplier organization to deliver a consistent defect-free product with the support from their organization such as procurement leaders.

Supplier or manufacturer will perceived supplier quality engineer job is to make life difficult for them, others will think supplier quality engineer always enjoy life at supplier site. Refer to the below video which will walk you through exactly what a supplier quality engineer do, and what are the skill set required.

December 28, 2021

Why supplier quality management is important to prevent disruption of supply chain in 2021?

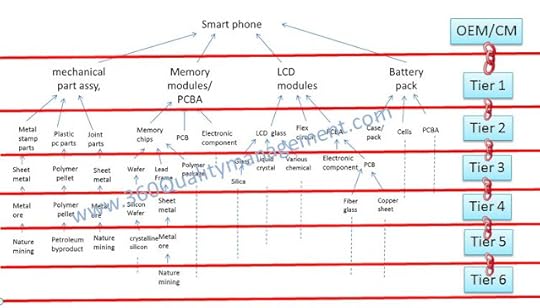

In today world, there is no one entity that is able to transform raw materials from natural resources completely too finished goods for the mass consumer market or end users. The transformation of raw material to semi-finished goods and finally finished goods took place in several manufacturing facilities which form a supply chain. Material supply chain links upstream raw material suppliers to downstream consumer market through multitier supplier.

For example, smartphone manufacturer will assemble parts from memory card modules, PCBA, battery pack, mechanical part assembly, frame which are procure from various tier one suppliers. Tier one suppliers in turn will either have capability to assemble lower level semi-finished goods to a module assembly or fabricate parts from semi processed raw materials. An example would a battery module manufacturer will procure battery cells from supplier and assembled into battery module or they would also have tier 2 capability to produce their own battery cells.

Most of the worlds manufacturing hubs are concentrated in Asia mainly China and majority of the consumer are outside of Asia such as US. This means we will have a long chain from manufacturing of the parts to the consumer.

According to a Bloomberg article by Anjani Trivedithe world is marred by disruption in supply which impact the global market. This is cause by lack of trust along supply chain and the consumer will feel the pain of price increase with limited supply. This happen due to the lack of trust. Therefore the next question would be how to cultivate trust a long the supply chain. Most of the company who are suffering from lacking of supplier trust are due no or poor supplier quality management program.

A good supplier quality management program must in place to gain trust and resulted in

Supplier is able to deliver consistent good quality partOn time delivery At best price for both parties

1.The criteria for a good supplier quality management are

Systematic approach in Essential areas such as supplier qualification, product qualification etcWell supplier quality management professional to execute the program

To learn about systematic approach in supplier quality management do refer to this link or click on the photo below

September 20, 2021

Supplier Quality Audit Plan for New Suppliers

The purpose of the onsite audit is to assess the supplier capability to produce consistently good quality parts.

You will need to work with your procurement team on the supplier's selection process for a project. Brief them importance of SQE early involvement for you to understand each supplier better and then establish an audit plan. There is no such thing as supplier is going to ship the part tomorrow and you are ask to audit them today. Supplier and SQE engagement should be 4-6 months ahead before they can supply the 1st part shipment according to the development schedule. You will also need to prepare for the supplier audit plan.

The SQE supplier audit plan should consist of:-

Supplier contact detailsAudit ground rulesSQE audit scheduleEstablish quality audit checklist Set Audit dateAudit notification

Items

Details

1

Supplier contact details

Who are the main contact point. Get supplier organization chart to understand who are the key person in key dept quality, process,

2

Audit ground rules

Establish a set of audit ground rules where supplier must ready to procedures, objective evidence and records during SQE onsite audit, etc.

3

Audit schedule

SQE should establish a schedule which covers end to end of the process start from material receiving, manufacturing process till shipment. All sub process must be audited as well.

4

Establish quality audit checklist

SQE should establish the audit checklist for quality system and process base on their expertise in commodity process and quality engineering. You can down load a copy of how to develop audit checklist on the resource page of this website

5

Set the audit date

The audit date had to match supplier production schedule to produce the similar part of interest

6

Audit notification

Once all the above items are ready, send audit notification to suppliers

Audit plan is part of audit preparation process in supplier audit phase. Supplier audit phase is consist of audit preparation, performing audit, reporting result and audit closure. It does not matter whether it is an onsite or remote audit, the process is still the same.

You can enroll in my course @ Udemy for more detail supplier quality audit which explains

1. Different types of supplier audit with quality system and quality process audit checklist for download

2. The four supplier audit phases

3. Auditing techniques which will enable you to become an expert in quality audits

You can click on the image for link to this course or scan the QR code :-

March 17, 2021

What is the difference between lean and six sigma - Part 2

In this section I shall give an overview of lean.

Lean is a culture which focuses on creating “value” to the customer through a culture of continuous improvement and focus on reduction/elimination of waste. Value in this context means

customer is willing to pay for activity which involve in transforming the raw material to final product.Activity must transform the part (inspection is not counted as there is no transformation work involve, there is no difference in physical aspect of the part before and after inspection)Do it right the first time

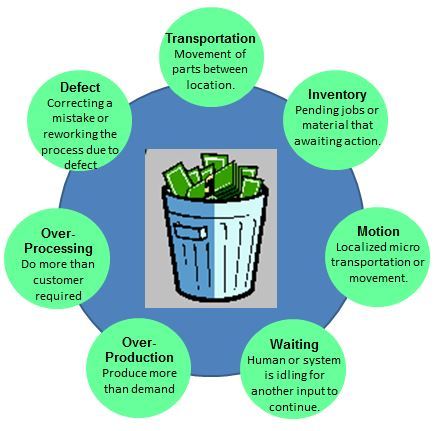

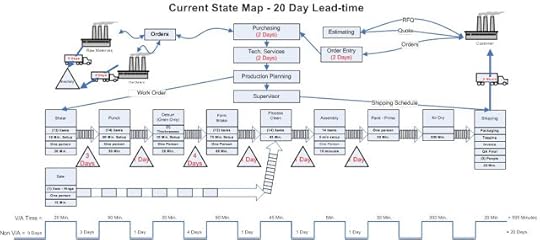

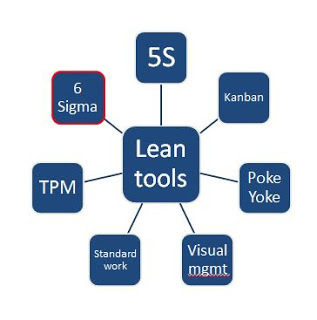

Waste in the definition of lean refer to the 7 waste as per below. Waste need to be identified through value stream mapping. Value stream map is a depiction of entire production(material and information) flow which include non value and value added activities to create a product. Value stream mapping is an exercise to create a value stream map by charting all current activities required to create a product and include some relevant information such as cycle time, defect rate etc. Once the current value stream map is completed, the team will be able to see all activities and identify waste follow by envision the future state. In order to achieve future state map, there must improvement plan (known as kaizen) to address the waste either by reduction and elimination to simplify the process. Lean tools which can be used to manage waste such as 5S, standard work, pull system, visual management, poke-yoke, Kanban etc.

7 Waste In a value stream

7 Waste In a value stream An Example of a value stream map

An Example of a value stream mapSix sigma is a problem solving approach originated from American organization which focus on sample data collection which represent population with lots of statistical analysis of a tactical problem. Lean is a management culture was practiced by Japanese which focus on observing all the process for product creation in the value stream to identify waste. Six sigma focus on data, lean focus on “learning to see” (refer to book of the same title by John Shook et. al).

In my opinion, six sigma can be part of lean. Six sigma can be used as a tool in kaizen as it is the best tool in variation reduction related to product defect, thus reduce waste related to defect. However lean can NEVER part of six sigma, at most lean tools can be used as an approach in improvement action plan during the improve phase of a six sigma project.

Some of the common lean tools, six sigma could be one of the lean tools to address defect waste

Some of the common lean tools, six sigma could be one of the lean tools to address defect wasteDue to lean tools is simple to use as lean is about simplification, many companies had adopted lean tools such as 5S, poke yoke etc. globally. Hard core six sigma organization had also deploy lean tools and thus this could be the beginning of lean six sigma term. Many companies end in confusion when they try to embrace six sigma as a culture using the six sigma approach to solve every problem!!!!The table show the comparison between lean and six sigma

Six sigma Lean Purpose To reduce a critical to quality metric data variation Bring value to customer through elimination of waste by striving for continuous improvement What it is Tool Culture Approach Phase by phase with data collection Overall value stream mapping through gemba walk of observing the activity Application area Point to point improvement Throughout supply chain Expertise requirement Statistic People management

A company does not qualify as a lean culture company by just adopting a few lean tools. Lean culture is about management leadership creating a work place which respect its worker who bring value to product by eliminating waste through continuous improvement. A real lean company will not hire excessive worker as there is not much waste to be managed and then later on fire when the worker is not needed. Lean culture company is able to do more with less to achieve consistent good quality product with minimal waste. Both Lean and six sigma is NOT magic which enable wealth creation of a corporation. In order to practice both lean and six sigma successfully, an organization would require a skill workforce with discipline. Unfortunately discipline had become rare commodity in today world which attribute to why many company failed eventually.

Refer to this video for more details

January 31, 2021

Zero defect a Myth or a reality - Organization accountability

In a normal situation, consumers only buy one product and thus the product must be functioning for its intended usage and specification. This means a product or service supplier to end consumer only get one chance to show their product is of good quality. Therefore, all products sold to the consumer market should achieve zero-defect or a very low defect rate such as six sigma quality which is equal to 3.4 defects in one million parts.

Product with zero defects is a dream of every organization. The next big question would be what it takes to achieve zero defects. In the modern world, the end product which reaches the end-user or consumer goes through a very long supply chain, from mother nature raw material such metal, silicon wafer, petrol chemical by-product to form into piece part assemble into sub-assembly and then join together to become final assembly.

All the touchpoint throughout the supply chain will increase error opportunity which could induce defect in a product. Refer to this link on the concept of the supply chain.

The most important condition to strive for the perfection of zero defect is an overall product design with design for manufacturability, serviceability, consumer etc in mind. Quality awareness must start right from the design of the product.

Unfortunately, most of the design only focuses on the functionality of the product which resulted in poor manufacturability, the limited supply chain of material and complicated product which is not user friendly.Many organizations did not realize that zero-defect must be designed in from raw material to piece part to sub-assembly to final assembly. The irony is that those organizations thought manufacturing process can compensate for the poor design and limited material supply base.

Very often a company tend to take short cut design process of a product to save on design cost and time to market which uses substandard material. This had created a ripple effect where company have to live with poor design, spend a huge amount of money to hire resources downstream to manage complicated manufacturing process for the infinite duration of time.

I will share more about design for manufacturability concept which leads to the zero-defect product in the next article. Please do follow this website by clicking on "Follow" on the top right sidebar. I have created a youtube video to explain more on this topic.

January 23, 2021

What is the difference between lean and six sigma - Part 1

When we approach the 21stcentury, lean concept practice by Toyota caught the attention of the western world when Dr. Womack et al. release an iconic book about lean (The Machine That Changed the World) in the 90s. This book was based on their research in MIT about innovative management and production system use in Toyota. As lean tools are quite simple and easy to adopt, a lot of company start to use the popular tools such as 5s, standard work, poke-yoke (error proof), kaizen etc., with almost immediate results seen. Thus lean slowly take over six sigma as the groundbreaking tool in production and management.

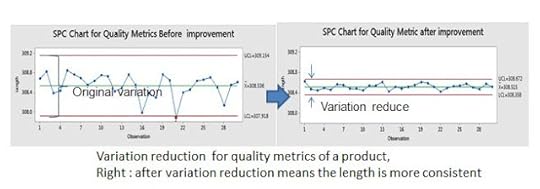

By the time lean become popular, many organizations had already adopted six sigma “culture” religiously. At the same time most management does not want to lose out to company who embraced lean which had gain a block buster results, they start to assimilate lean tools and thus the beginning of term lean six sigma. Most of the training companies start to rid the wave of trend by offering Lean six sigma course. Lean six sigma is a very misguided term as both lean and six sigma are entirely different. Lean is a culture and six sigma is an approach to reduce variation contributed by poor process control. Six sigma could be part of lean and not vice versa. Six sigma is a structured variation reduction methodology. I found that a lot of engineers who had study or deploy six sigma still do NOT understand the real meaning of variation reduction. I would like to use the scenario below to illustrate the meaning of variation reduction. A manufacturing company found that their product could not customer specification for length of 308.50+/-0.30 (308.20-308.80). Base on the data collected for product length and plotted on the control chart on the left, it seems some data already exceed or below spec. The company had to reject the product which does mean customer spec. The quality engineer decided to use six sigma approach to improve the process in order to produce parts which consistently meet customer spec. After improvement, the quality engineer collect the product length data and plot in control chart (right). It was found the product length variation had reduced with tighter control limit as compare to the chart on the left. It also show that the product length can consistently meet customer spec, Thus variation of the product length had reduced using six sigma approach.

Six sigma phase by phase approach from define, measure, analyze, improve and control is to ensure that variation quality characteristic of the product is reduce or bring to target per customer spec or both.

Six sigma will only meaningful in a process improvement if useful data are collected diligently with big enough sample size to study the current trend and make a statistical conclusion on the population behavior. Data collection could focus on one or at the most two parameters which are critical to quality identified through mapping customer requirement. After improvement, data is collected again and analyzed statistically to ensure the trend had improved for overall population. Therefore it is very statistical based tactical tools to achieve customer requirement be on objective specification of certain critical quality metric and we must be able to measure the quality metric.

Do refer to this video for more details

January 6, 2021

Proactive leadership in Quality management

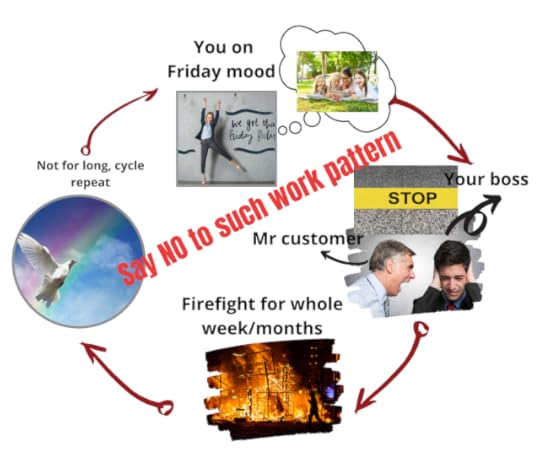

Saying no to such work pattern requires a lot of leadership, planning, courage and communications.

Sometimes we are overwhelmed with so many issues that we are lost and unable to lead ourselves out of those situations. Therefore we continued to firefight for the rest of our working lives and hated our work.

The situation is aggravated if you working for management does not have a clear understanding of what is going on and no objective how to minimize even prevent problems.

We must treat all problems as our enemy, lead ourselves and our team to go to war to conquer this enemy.

Know yourself well, know your enemy even better, a hundred battles fought a hundred battles win.

This is a famous quote by Sun Tzu, a military strategist found in the Art of War, an ancient Chinese military treatise. It starts with taking the lead to understand the problem very well, such as asking questions of what, where, when, who and how and gathering accurate data. This seems to be a simple step; however, many had failed due to lack of knowledge and perspective to look at the problem differently. Once the problem is well defined, we should have some insights if the problem is within our capability to solve or there is no immediate solution. Learn to acknowledge that the problem cannot be prevented with current resources is essential for us to manage the problem.

This is where the problem gets bigger as everyone is only thinking of solving it instead of managing it. I will discuss more about it in the future.

Once you know the problem, then planning is needed to establish a solution to prevent or manage the problem. A problem that is well defined will make planning for action is more straightforward. This will require knowledge gain from learning and experience. Our knowledge is will help us to search for the eureka moment in planning for a solution. We must have the courage to plan for a solution which could go beyond the four walls of the manufacturing facility.

Improvement in minimizing or prevent problem will not happen by just planning. We need to put the problem and action plan into the right perspective so that we can communicate clearly to the management and team member.

Communication to the management is very important to influence the management to support and invest in resources to make the plan into reality.

We must eliminate the victim’s mentality and be proactive in leading ourselves towards a better work-life as the first step towards in being control. If you are in a leadership position, ensure that you are part of the solution to the problem.