What is the difference between lean and six sigma - Part 2

By now we should have a better understanding of six sigma. More detail about six sigma can be found in my previous posting, http://www.360qualitymanagement.com/2017/09/continuous-quality-improvement-program.html.

In this section I shall give an overview of lean.

Lean is a culture which focuses on creating “value” to the customer through a culture of continuous improvement and focus on reduction/elimination of waste. Value in this context means

customer is willing to pay for activity which involve in transforming the raw material to final product.Activity must transform the part (inspection is not counted as there is no transformation work involve, there is no difference in physical aspect of the part before and after inspection)Do it right the first time

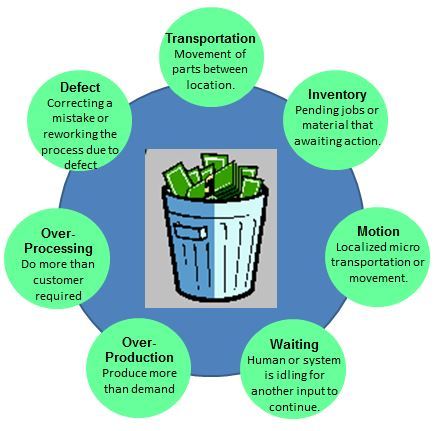

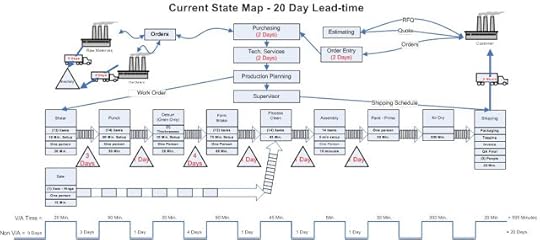

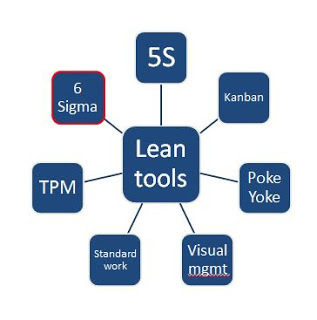

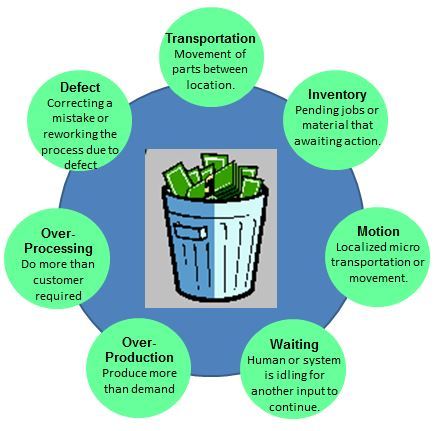

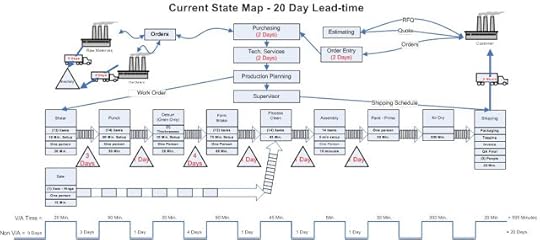

Waste in the definition of lean refer to the 7 waste as per below. Waste need to be identified through value stream mapping. Value stream map is a depiction of entire production(material and information) flow which include non value and value added activities to create a product. Value stream mapping is an exercise to create a value stream map by charting all current activities required to create a product and include some relevant information such as cycle time, defect rate etc. Once the current value stream map is completed, the team will be able to see all activities and identify waste follow by envision the future state. In order to achieve future state map, there must improvement plan (known as kaizen) to address the waste either by reduction and elimination to simplify the process. Lean tools which can be used to manage waste such as 5S, standard work, pull system, visual management, poke-yoke, Kanban etc. 7 Waste In a value stream

7 Waste In a value stream

An Example of a value stream map

An Example of a value stream map

Six sigma is a problem solving approach originated from American organization which focus on sample data collection which represent population with lots of statistical analysis of a tactical problem. Lean is a management culture was practiced by Japanese which focus on observing all the process for product creation in the value stream to identify waste. Six sigma focus on data, lean focus on “learning to see” (refer to book of the same title by John Shook et. al).

In my opinion, six sigma can be part of lean. Six sigma can be used as a tool in kaizen as it is the best tool in variation reduction related to product defect, thus reduce waste related to defect. However lean can NEVER part of six sigma, at most lean tools can be used as an approach in improvement action plan during the improve phase of a six sigma project. Some of the common lean tools, six sigma could be one of the lean tools to address defect waste

Some of the common lean tools, six sigma could be one of the lean tools to address defect waste

Due to lean tools is simple to use as lean is about simplification, many companies had adopted lean tools such as 5S, poke yoke etc. globally. Hard core six sigma organization had also deploy lean tools and thus this could be the beginning of lean six sigma term. Many companies end in confusion when they try to embrace six sigma as a culture using the six sigma approach to solve every problem!!!!The table show the comparison between lean and six sigma

Six sigma Lean Purpose To reduce a critical to quality metric data variation Bring value to customer through elimination of waste by striving for continuous improvement What it is Tool Culture Approach Phase by phase with data collection Overall value stream mapping through gemba walk of observing the activity Application area Point to point improvement Throughout supply chain Expertise requirement Statistic People management

A company does not qualify as a lean culture company by just adopting a few lean tools. Lean culture is about management leadership creating a work place which respect its worker who bring value to product by eliminating waste through continuous improvement. A real lean company will not hire excessive worker as there is not much waste to be managed and then later on fire when the worker is not needed. Lean culture company is able to do more with less to achieve consistent good quality product with minimal waste. Both Lean and six sigma is NOT magic which enable wealth creation of a corporation. In order to practice both lean and six sigma successfully, an organization would require a skill workforce with discipline. Unfortunately discipline had become rare commodity in today world which attribute to why many company failed eventually.

Refer to this video for more details

In this section I shall give an overview of lean.

Lean is a culture which focuses on creating “value” to the customer through a culture of continuous improvement and focus on reduction/elimination of waste. Value in this context means

customer is willing to pay for activity which involve in transforming the raw material to final product.Activity must transform the part (inspection is not counted as there is no transformation work involve, there is no difference in physical aspect of the part before and after inspection)Do it right the first time

Waste in the definition of lean refer to the 7 waste as per below. Waste need to be identified through value stream mapping. Value stream map is a depiction of entire production(material and information) flow which include non value and value added activities to create a product. Value stream mapping is an exercise to create a value stream map by charting all current activities required to create a product and include some relevant information such as cycle time, defect rate etc. Once the current value stream map is completed, the team will be able to see all activities and identify waste follow by envision the future state. In order to achieve future state map, there must improvement plan (known as kaizen) to address the waste either by reduction and elimination to simplify the process. Lean tools which can be used to manage waste such as 5S, standard work, pull system, visual management, poke-yoke, Kanban etc.

7 Waste In a value stream

7 Waste In a value stream An Example of a value stream map

An Example of a value stream mapSix sigma is a problem solving approach originated from American organization which focus on sample data collection which represent population with lots of statistical analysis of a tactical problem. Lean is a management culture was practiced by Japanese which focus on observing all the process for product creation in the value stream to identify waste. Six sigma focus on data, lean focus on “learning to see” (refer to book of the same title by John Shook et. al).

In my opinion, six sigma can be part of lean. Six sigma can be used as a tool in kaizen as it is the best tool in variation reduction related to product defect, thus reduce waste related to defect. However lean can NEVER part of six sigma, at most lean tools can be used as an approach in improvement action plan during the improve phase of a six sigma project.

Some of the common lean tools, six sigma could be one of the lean tools to address defect waste

Some of the common lean tools, six sigma could be one of the lean tools to address defect wasteDue to lean tools is simple to use as lean is about simplification, many companies had adopted lean tools such as 5S, poke yoke etc. globally. Hard core six sigma organization had also deploy lean tools and thus this could be the beginning of lean six sigma term. Many companies end in confusion when they try to embrace six sigma as a culture using the six sigma approach to solve every problem!!!!The table show the comparison between lean and six sigma

Six sigma Lean Purpose To reduce a critical to quality metric data variation Bring value to customer through elimination of waste by striving for continuous improvement What it is Tool Culture Approach Phase by phase with data collection Overall value stream mapping through gemba walk of observing the activity Application area Point to point improvement Throughout supply chain Expertise requirement Statistic People management

A company does not qualify as a lean culture company by just adopting a few lean tools. Lean culture is about management leadership creating a work place which respect its worker who bring value to product by eliminating waste through continuous improvement. A real lean company will not hire excessive worker as there is not much waste to be managed and then later on fire when the worker is not needed. Lean culture company is able to do more with less to achieve consistent good quality product with minimal waste. Both Lean and six sigma is NOT magic which enable wealth creation of a corporation. In order to practice both lean and six sigma successfully, an organization would require a skill workforce with discipline. Unfortunately discipline had become rare commodity in today world which attribute to why many company failed eventually.

Refer to this video for more details

Published on March 17, 2021 15:36

No comments have been added yet.